Master Products

This article covers the configuration and use of master product groups in Kitchen CUT.

Master Products allow users to group similar or interchangeable products under a unified control group, streamlining ordering, inventory, costing, and sales logic across suppliers, sizes, and formats. These groups help reduce duplication, optimise purchasing behaviour, and ensure consistent system performance.

What Are Master Products?

A Master Product Group is used to combine variations of the same item — typically:

-

Products with different pack sizes (e.g. 70cl bottle, 1L bottle)

-

Products sourced from multiple suppliers but serving the same function

This grouping simplifies the ordering interface, improves stock management, and ensures accurate costing and sales tracking when products are interchangeable.

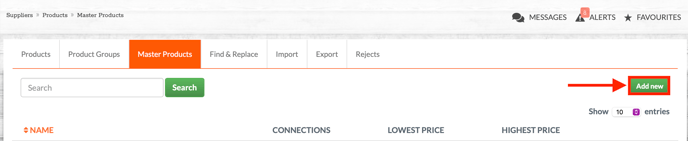

How to Create a Master Product

1. Creating a Master Product Group

Go to:

2. Set-up the Group

You will be prompted to complete the following setup:

- Group Name (Required) - The internal name for the Master Product Group

- Category (Required) - Assign the group to a product category (e.g. Spirits, Crisps, Dry Goods)

- Default UOM Type (Required) - Choose the unit of measure used for cost (e.g. each, g, kg, ml,)

- Default Secondary Unit Type - Select the secondary unit if applicable

- Default Pack Size Type - Defines how the product is packed or purchased (e.g. bottle, box)

Click Create .

3. Add Products to the Group

Once created, you can add individual products into the group. These should be functionally identical items, such as:

-

The same ingredient in different formats

-

The same item from different suppliers

.png?width=688&height=297&name=image%20(15).png)

📌 Products within a group should logically substitute for one another in recipes, ordering, or inventory.

⚙️ Configuring Master Product Behaviour

Within each Master Product Group, you can control how the system behaves when multiple alternatives are available. The configuration for ordering and inventory are independent and can be set separately. You can find these settings by following :

Settings > Ordering/Inventory > Master Products

Order Priority

Choose how the system prioritises alternatives when more than one is available:

-

Highest Value – Prioritises the most expensive product

-

Lowest Value – Prioritises the cheapest product

-

Average – Uses an average logic across options

Alt. Behaviour

Determines how the alternatives are presented to users:

- Lock - Only the priority product can be ordered. Other products within the group remain visible but will be greyed out.

- Unlock - All alternatives are visible and selectable.

- Hide - Only the priority product is shown. Others are hidden entirely.

These settings ensure purchasing teams follow the correct strategy for cost control, availability, or supplier preference.

Ordering Impact

When placing a purchase order, the system groups all Master Product members into a single visual item. Depending on the configuration, users will:

-

See only the preferred item

-

Be able to select any item

-

Be prevented from choosing anything but the defined priority

This simplifies the interface and reduces errors during ordering.

Costing & Sales Impact

The Master Product configuration also applies to menu costing and sales mapping:

-

Products within a Master Product Group will follow the same order priority and alt. behaviour rules when being selected or mapped in:

-

Menu costing

-

Menu items (EPOS mapping)

-

Sales tracking

-

Depending on your configuration:

-

Locked groups will only allow the primary product to be selected

-

Hidden alternatives will not appear to the user during costing or mapping

-

Unlocked groups allow full flexibility across all members

This ensures product substitution is controlled consistently across all parts of the system.

Inventory Impact

Master Products also affect how inventory is depleted.

If the currently linked product for a menu item depletes to zero, and it belongs to a Master Product Group:

-

The system will begin depleting the next item in the group

-

This follows your system’s inventory configuration — either FIFO (First-In-First-Out) or LIFO (Last-In-First-Out)

This ensures continuous tracking even when substitutes are used and reduces gaps in reporting.

This ensures continuous tracking even when substitutes are used and reduces gaps in reporting.

💡 Best Practices

-

Use Master Products for items like spirits, dry goods, or produce where substitutions are common.

-

Regularly review group configurations to ensure priority and behaviour settings align with purchasing goals.

-

Monitor stock levels to ensure Master Product substitution works correctly with FIFO/LIFO settings.

❓FAQs

Can I include products from different categories in one Master Product?

No — products should belong to the same category and serve the same function to ensure proper substitution.

Do Master Products affect recipe costings?

No — recipes are still costed based on the assigned product, but substitutions will affect stock depletion and reporting.

Can I override Alt. Behaviour during ordering?

No — behaviour is controlled by the configuration set at the Master Product level.

🆘 Need Help?

📧 Email Support: support@kitchencut.com

📝 Submit a Ticket: Submit a ticket